ironing board cover 125cm x 45cm_washing machine full cover

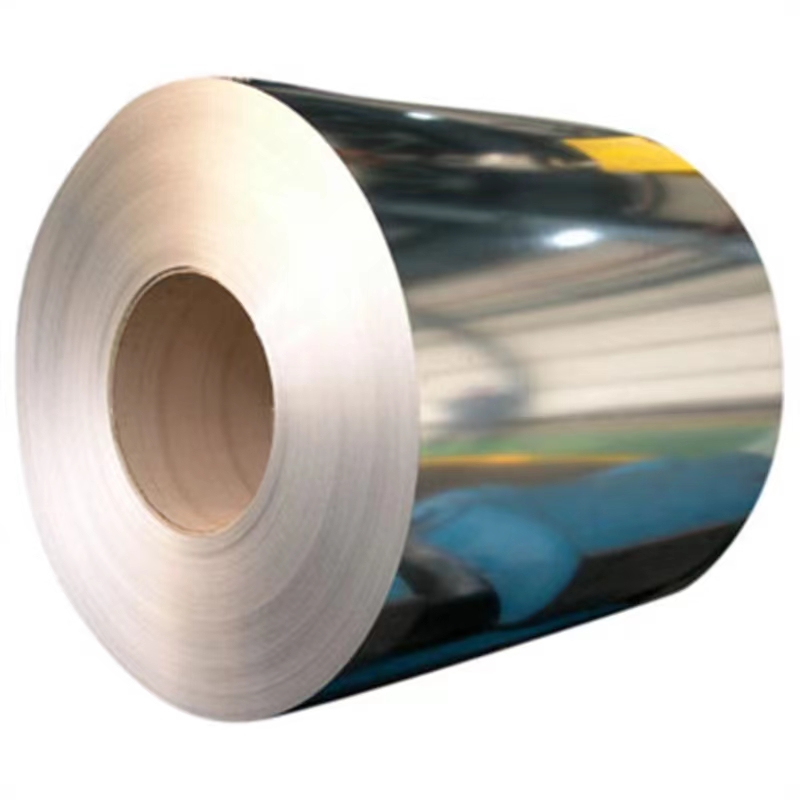

Sheet metal roof covering factories play an essential role in the roofing industry, providing the necessary materials and products for these roofing solutions. These factories are equipped with advanced machinery and technology to produce high-quality metal sheets, trims, and accessories designed to meet stringent industry standards. The manufacturing process typically involves cutting, bending, and forming sheet metal into various shapes and sizes, ready for installation.

sheet metal roof covering factories

Quality control is another critical aspect of galvanized iron square pipe factories. The production process involves stringent quality checks to ensure that the finished products meet the necessary specifications. Various tests, including tensile strength and corrosion resistance assessments, are conducted to guarantee reliability and safety. This emphasis on quality not only protects the end-users but also bolsters the reputation of manufacturers in a competitive market.

One of the primary benefits of sandwich sheet roofing is its superior insulation properties. Buildings equipped with sandwich sheet roofs tend to maintain consistent indoor temperatures, leading to reduced heating and cooling costs. This aspect alone makes them a popular choice for commercial, industrial, and even residential applications.

sandwich sheet roof manufacturer

4. Environmental Impact In an era where sustainability is crucial, heat reflective sheets contribute to reducing the urban heat island effect—a phenomenon where urban areas become significantly warmer than their rural surroundings due to human activities. By utilizing reflective roofing materials, cities can mitigate this warming effect, promoting a healthier environment.

buy heat reflective sheet for roof manufacturers