Current location:Home > large padded ironing board cover_personalised ironing board cover >

large padded ironing board cover_personalised ironing board cover

Black table covers, often underappreciated in their role, have emerged as essential components in bo...

2025-08-15 02:40

Bàn là và tấm phủ của nó đóng vai trò quan trọng trong việc ủi đồ hàng ngày, góp phần giữ gìn sự ngă...

2025-08-15 02:31

Угаалгын машин, хуухны хэсэнгийн хальс Угаалгын машин, хуухны хэсэнг үүсгэхэд зориулсан хальс нь гэр...

2025-08-15 02:11

Heavy-duty plastic table covers have become an indispensable asset for various events and settings,...

2025-08-15 01:24

The Importance of Sleeve Ironing Board Covers A Comprehensive Guide When it comes to ironing, many p...

2025-08-15 00:59

Угаалгын машин, хуухны хэсэнгийн хальс Угаалгын машин, хуухны хэсэнг үүсгэхэд зориулсан хальс нь гэр...

2025-08-15 00:51

Elevate your ironing experience with a metallic ironing board cover, an essential asset for anyone w...

2025-08-15 00:47

In the art of home organization and workspace efficiency, rolling cart liners have become an indispe...

2025-08-15 00:15

Choosing the perfect orange ironing board cover can transform an ordinary chore into a delightful ex...

2025-08-15 00:01

In recent years, fabric washing machine covers have evolved from a purely functional item to a styli...

2025-08-15 00:00

Latest articles

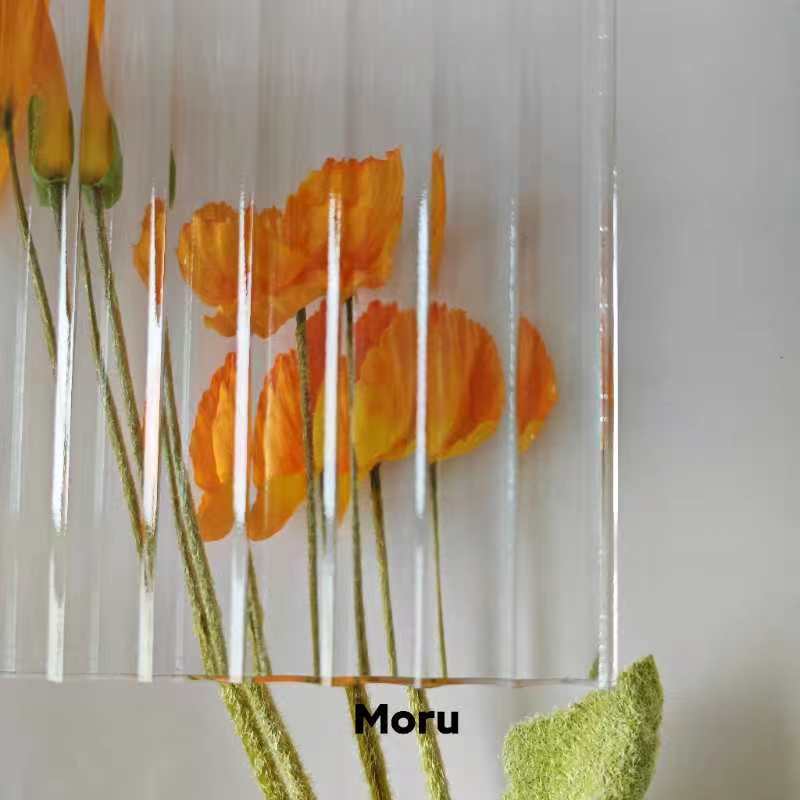

Moreover, reputable suppliers of 2mm float glass pride themselves on maintaining a consistently high product quality. They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws

They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws 2mm float glass supplier. As such, they employ stringent quality control measures from the melting phase to the packing stage, ensuring each sheet delivered to clients is free from waves, bubbles, and distortions.

2mm float glass supplier. As such, they employ stringent quality control measures from the melting phase to the packing stage, ensuring each sheet delivered to clients is free from waves, bubbles, and distortions.

They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws

They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws 2mm float glass supplier. As such, they employ stringent quality control measures from the melting phase to the packing stage, ensuring each sheet delivered to clients is free from waves, bubbles, and distortions.

2mm float glass supplier. As such, they employ stringent quality control measures from the melting phase to the packing stage, ensuring each sheet delivered to clients is free from waves, bubbles, and distortions.