cat ironing board cover_folding cart liner

The float glass production process begins with the melting of raw materials, including silica sand, soda ash, and limestone, at high temperatures. This molten mixture is then floated on top of molten tin, allowing the glass to spread evenly and form a continuous sheet. As the glass moves through the annealing lehr—a controlled cooling chamber—it gradually solidifies and is cut into standardized sheet sizes.

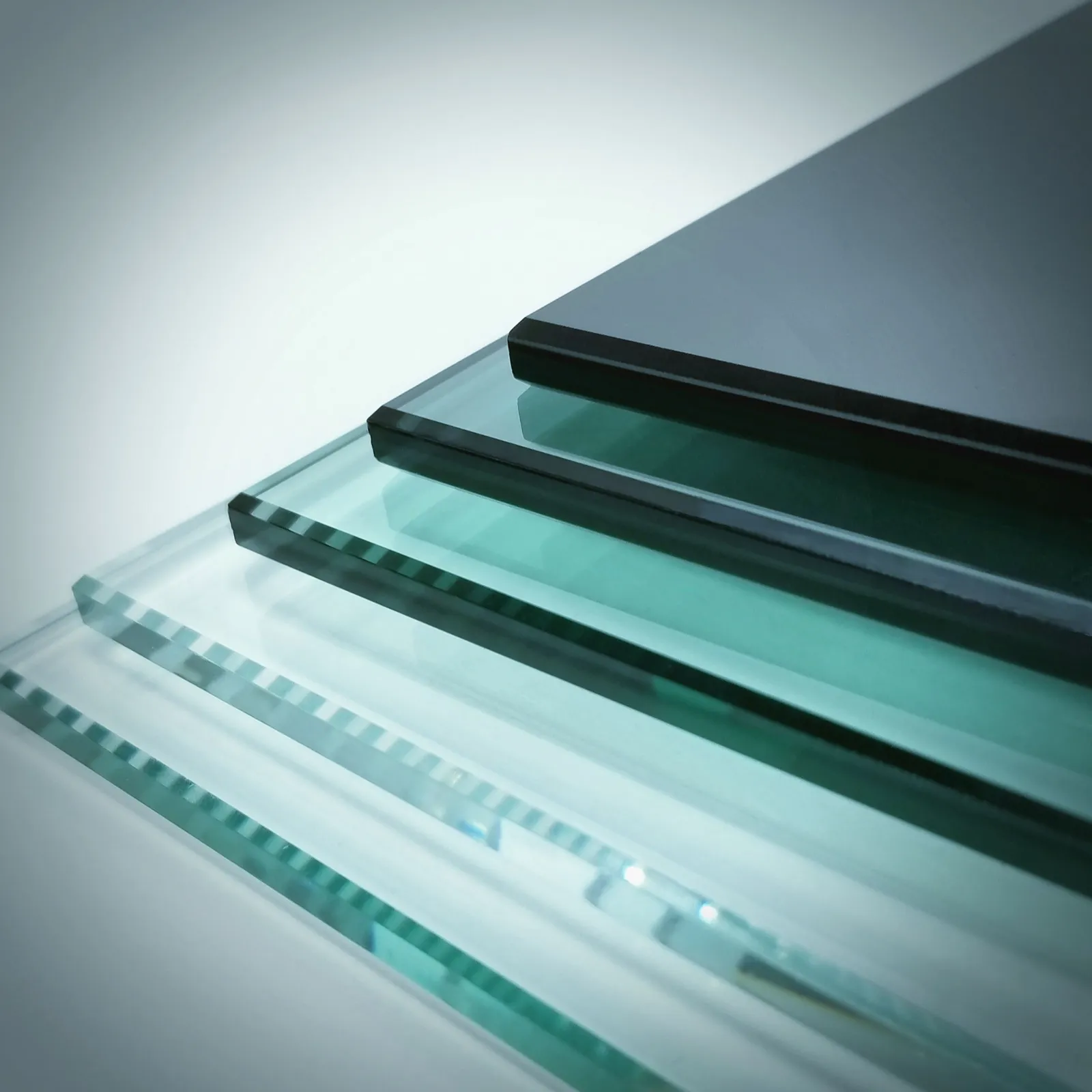

float glass sheets

In addition to the multiple panes of glass, insulated window units also feature low-emissivity (low-E) coatings on the glass surfaces. These coatings help to reflect heat back into the room, further reducing heat transfer through the windows. Low-E coatings also help to block harmful ultraviolet (UV) rays, which can fade furniture and flooring over time.

toughened float glass. The heat treatment process makes the glass more resistant to sudden changes in temperature, which reduces the risk of thermal stress fractures. This makes toughened glass suitable for use in environments where temperature fluctuations are common, such as in kitchens, bathrooms, and outdoor structures.