Current location:Home > reflective ironing board cover_aboriginal tablecloth >

reflective ironing board cover_aboriginal tablecloth

In recent years, fabric washing machine covers have evolved from a purely functional item to a styli...

2025-08-15 19:33

In the realm of household chores, ironing often ranks as one of the more mundane tasks. However, the...

2025-08-15 18:28

Iron cover boards, integral to modern infrastructure and construction, offer substantial advantages...

2025-08-15 18:21

When considering the use of heat styling tools like hair straighteners, protection becomes a crucial...

2025-08-15 18:16

The Charm of Thick Table Cloths Elevating Your Dining Experience When it comes to setting the perfec...

2025-08-15 18:02

Promotional tablecloths have become an indispensable asset for businesses aiming to amplify their br...

2025-08-15 17:25

Choosing the right washing machine cover is an essential decision for anyone who wants to protect th...

2025-08-15 17:16

The search for a perfect ironing board cover can often be tedious and frustrating, leaving many peop...

2025-08-15 17:11

Choosing the right canvas ironing board cover is crucial for achieving wrinkle-free clothes while en...

2025-08-15 17:09

The turquoise ironing board cover is more than just a vibrant addition to your laundry room. It repr...

2025-08-15 16:58

Latest articles

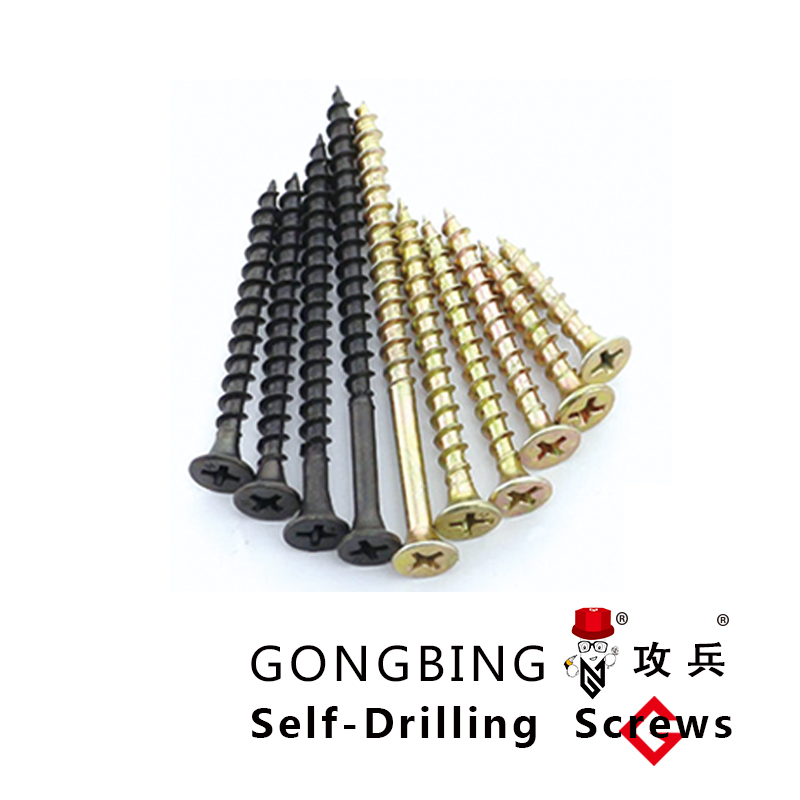

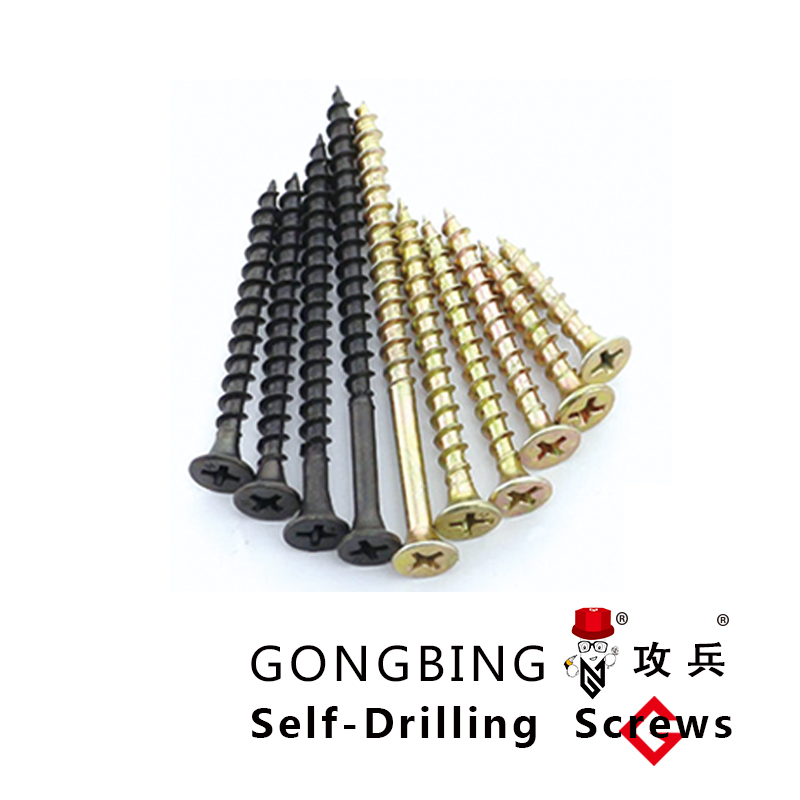

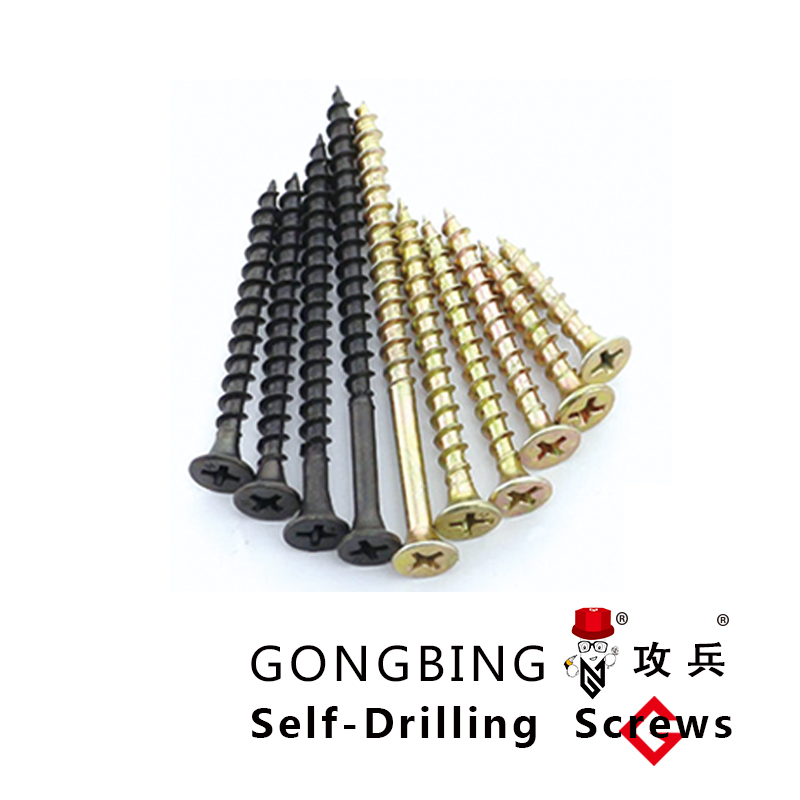

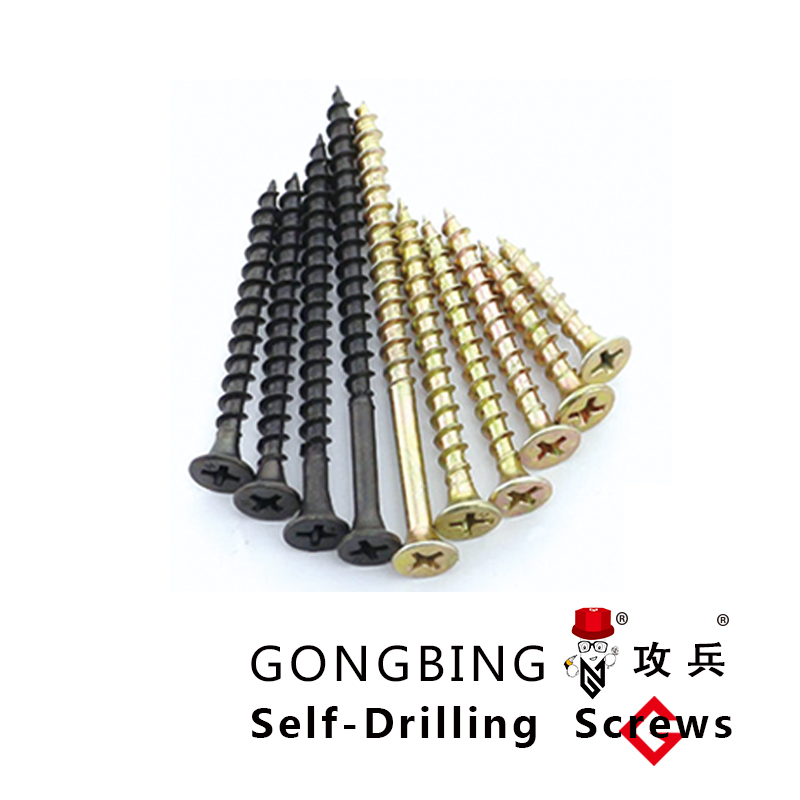

But it's not just the efficiency and productivity of the factory that sets it apart; it's also the commitment to quality. Every screw that leaves the factory is subjected to rigorous testing to ensure that it meets the highest standards. This attention to detail has earned the factory a reputation for producing the best chipboard screws on the market This attention to detail has earned the factory a reputation for producing the best chipboard screws on the market This attention to detail has earned the factory a reputation for producing the best chipboard screws on the market This attention to detail has earned the factory a reputation for producing the best chipboard screws on the market

This attention to detail has earned the factory a reputation for producing the best chipboard screws on the market This attention to detail has earned the factory a reputation for producing the best chipboard screws on the market chipboard screw factory.

chipboard screw factory.

This attention to detail has earned the factory a reputation for producing the best chipboard screws on the market This attention to detail has earned the factory a reputation for producing the best chipboard screws on the market

This attention to detail has earned the factory a reputation for producing the best chipboard screws on the market This attention to detail has earned the factory a reputation for producing the best chipboard screws on the market chipboard screw factory.

chipboard screw factory.Installation involves several steps. First, holes are drilled into the foundation to the exact depth and diameter required for each bolt. The bolts are then inserted, often with a nut and washer attached at the end to maintain position. A chemical grout or concrete is then poured around the bolt to fill the void, creating a strong mechanical connection. Once the concrete has cured, the nuts are tightened, securing the structure to the foundation Once the concrete has cured, the nuts are tightened, securing the structure to the foundation Once the concrete has cured, the nuts are tightened, securing the structure to the foundation Once the concrete has cured, the nuts are tightened, securing the structure to the foundation

Once the concrete has cured, the nuts are tightened, securing the structure to the foundation Once the concrete has cured, the nuts are tightened, securing the structure to the foundation foundation bolt fixing.

foundation bolt fixing.

Once the concrete has cured, the nuts are tightened, securing the structure to the foundation Once the concrete has cured, the nuts are tightened, securing the structure to the foundation

Once the concrete has cured, the nuts are tightened, securing the structure to the foundation Once the concrete has cured, the nuts are tightened, securing the structure to the foundation foundation bolt fixing.

foundation bolt fixing.