Current location:Home > ironing board cover 102 x 44_industrial ironing board cover >

ironing board cover 102 x 44_industrial ironing board cover

In recent years, fabric washing machine covers have evolved from a purely functional item to a styli...

2025-08-16 10:54

For many households, ironing is a necessary chore, but it doesn't have to be mundane. Decorative iro...

2025-08-16 10:51

When striving for optimal efficiency in daily chores, small tabletop ironing board covers often go u...

2025-08-16 10:43

When it comes to ironing, having the right ironing board cover is essential for both functionality a...

2025-08-16 10:32

An ironing board cover measuring 125 x 38 cm is not just a household accessory; it is an integral co...

2025-08-16 10:27

عنوان مفرش الطاولة لطاولة ارتفاع 8 أقدام تعتبر الطاولات واحدة من العناصر الأساسية في أي مناسبة أو تج...

2025-08-16 09:18

The Importance of Choosing the Right Ironing Board Cover A Focus on 150 x 50 cm Sizes When it comes...

2025-08-16 09:16

Exploring the realm of ironing board covers can lead you into a world of unusual designs and feature...

2025-08-16 09:08

The Versatile Solution Sticky Table Covers In our fast-paced world, the demand for convenience and e...

2025-08-16 08:48

Selecting the right ironing board cover can significantly enhance the efficiency and experience of i...

2025-08-16 08:47

Latest articles

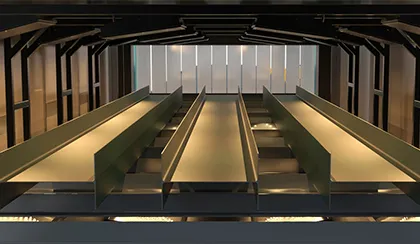

Automatic spray coating machines utilize advanced robotic systems to apply coatings evenly across surfaces

, eliminating the inconsistencies often associated with manual application processes. This precision ensures that coatings are applied with the exact thickness required, enhancing both the aesthetic and protective qualities of the final product. Experts in the field highlight the machine's capability to handle a variety of materials, from metals to plastics, making it a versatile choice for different industries.The importance of maintaining a clean and safe environment during welding cannot be overstated. When working with automated welding arms, one of the most significant challenges is managing the hazardous fumes and smoke generated during the welding process. This is where welding extraction arms come into play. These arms are specifically designed to capture fumes directly at the point of origin, ensuring that harmful particles are contained before they can spread throughout the workspace.