Current location:Home > non slip ironing board cover_red iron board cover >

non slip ironing board cover_red iron board cover

Selecting the right ironing board cover, especially one that measures 115 x 38 cm, can transform you...

2025-08-15 07:20

Choosing the right ironing board cover can significantly enhance your ironing experience, and when i...

2025-08-15 07:20

Choosing the right ironing board cover may not seem like a significant decision, yet it can dramatic...

2025-08-15 07:17

The Universal Ironing Board Cover A Must-Have for Every Home Ironing can sometimes feel like a tedio...

2025-08-15 06:56

Enhancing the aesthetic and functional qualities of outdoor spaces often begins with selecting the r...

2025-08-15 06:51

Exploring the world of flea market cart liners offers a unique avenue for both frequent vendors and...

2025-08-15 06:41

The perfect glove steamer can revitalize your daily routine, breathing fresh life into an old pair o...

2025-08-15 05:50

Tabletop covers, an often overlooked aspect of interior decoration, play a crucial role in both the...

2025-08-15 05:32

Table covers, a seemingly simple product, hold immense value in transforming dining experiences, whe...

2025-08-15 05:04

drawstring ironing board cover ....

2025-08-15 04:50

Latest articles

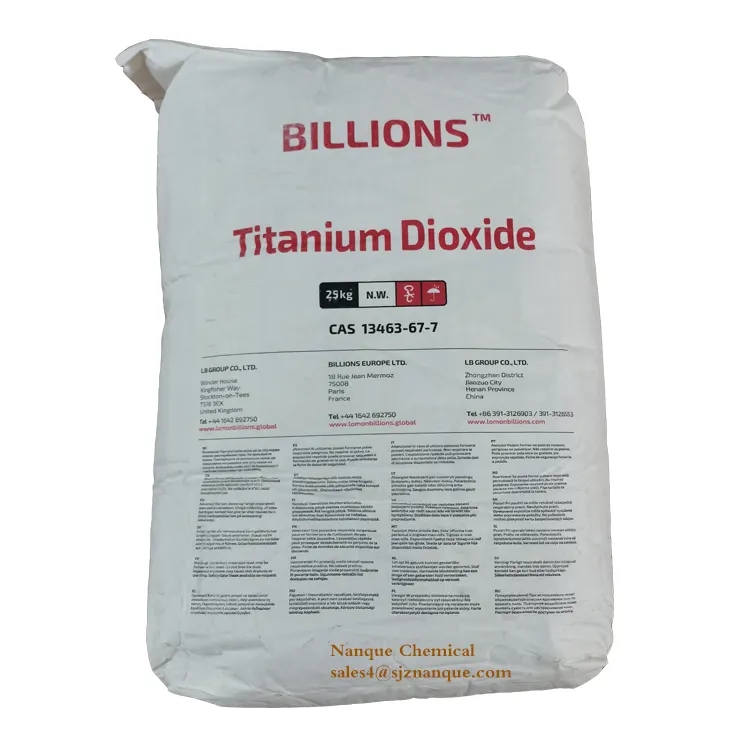

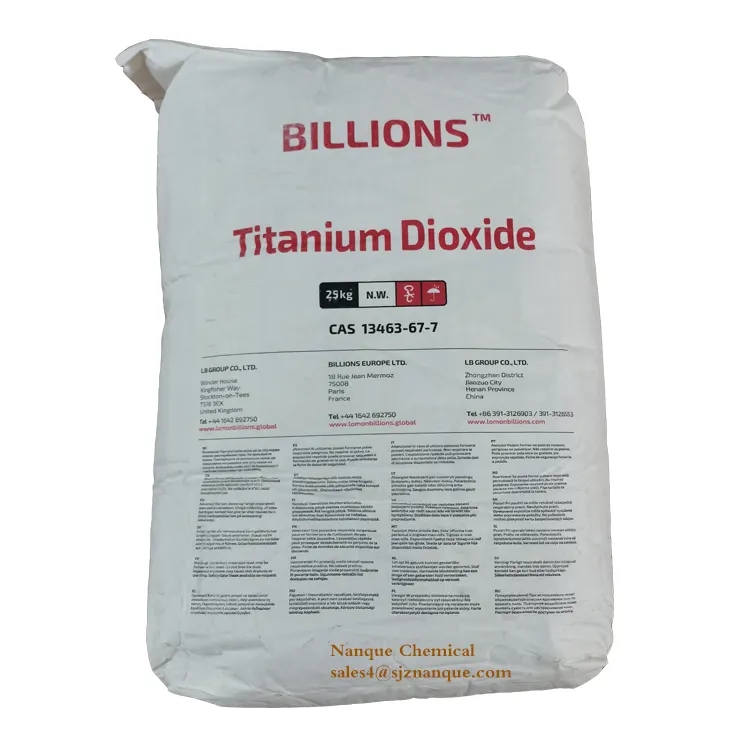

Thirdly, titanium dioxide is a semiconductor material with a wide bandgap energy of 3 6618 titanium dioxide.2 eV. This property makes it suitable for use in solar cells and other electronic devices. Titanium dioxide can be doped with other elements to improve its electrical conductivity and enhance its performance in these applications.

6618 titanium dioxide.2 eV. This property makes it suitable for use in solar cells and other electronic devices. Titanium dioxide can be doped with other elements to improve its electrical conductivity and enhance its performance in these applications.

6618 titanium dioxide.2 eV. This property makes it suitable for use in solar cells and other electronic devices. Titanium dioxide can be doped with other elements to improve its electrical conductivity and enhance its performance in these applications.

6618 titanium dioxide.2 eV. This property makes it suitable for use in solar cells and other electronic devices. Titanium dioxide can be doped with other elements to improve its electrical conductivity and enhance its performance in these applications.