Understanding Nappe Ajustée A Key Concept in Geology Nappe ajustée, a term derived from French geolo...

2025-08-16 02:14

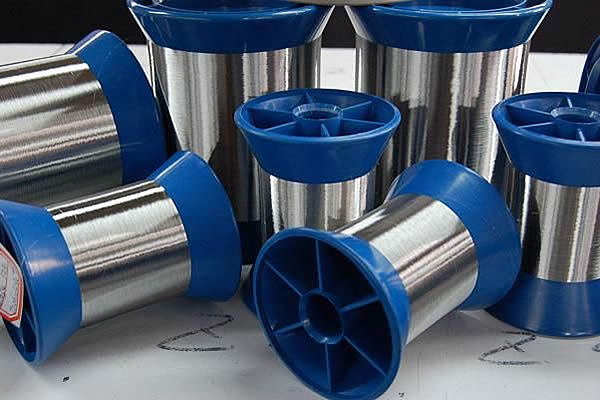

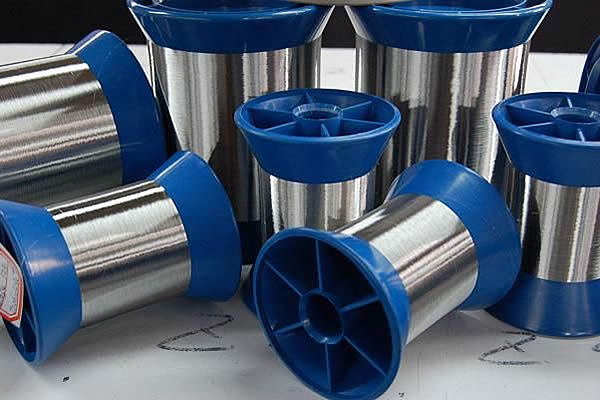

Additionally, it is used in filtering and screening operations during the processing of minerals and ores Additionally, it is used in filtering and screening operations during the processing of minerals and ores

Additionally, it is used in filtering and screening operations during the processing of minerals and ores Additionally, it is used in filtering and screening operations during the processing of minerals and ores heavy duty welded wire mesh.

heavy duty welded wire mesh. This is especially important for individuals with respiratory issues such as asthma or allergies This is especially important for individuals with respiratory issues such as asthma or allergies

This is especially important for individuals with respiratory issues such as asthma or allergies This is especially important for individuals with respiratory issues such as asthma or allergies windbreak cladding mesh. Additionally, windbreak cladding mesh contributes to reduced noise pollution, resulting in a quieter living space.

windbreak cladding mesh. Additionally, windbreak cladding mesh contributes to reduced noise pollution, resulting in a quieter living space.