Current location:Home > funky ironing board cover_12 x 42 ironing board cover >

funky ironing board cover_12 x 42 ironing board cover

Tabletop covers, an often overlooked aspect of interior decoration, play a crucial role in both the...

2025-08-15 09:48

In the realm of household chores, ironing often ranks as one of the more mundane tasks. However, the...

2025-08-15 09:12

For any home enthusiast or even a professional in the textile care industry, finding the perfect bla...

2025-08-15 09:12

Attending to daily household chores often seems mundane, yet choosing the right tools can transform...

2025-08-15 08:05

An ironing board cover is more than just a piece of fabric laid atop your ironing board; it is an in...

2025-08-15 08:01

As a seasoned SEO expert with years of experience in enhancing online visibility for niche products,...

2025-08-15 07:47

drawstring ironing board cover ....

2025-08-15 07:45

Transforming your ironing experience begins with the right accessory, and the 42 ironing board cover...

2025-08-15 07:26

The market demand for ironing board covers continues to grow, and consumers have increased require...

2025-08-15 07:15

Steamer gloves have revolutionized the way we approach hand care in environments where heat protecti...

2025-08-15 07:11

Latest articles

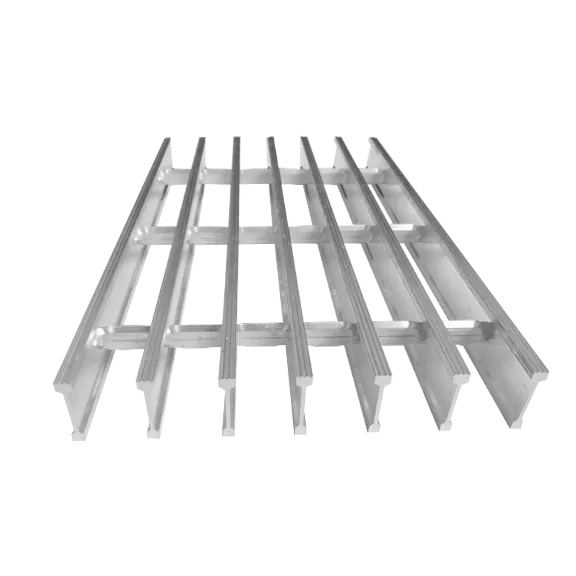

One of the primary advantages of galvanised steel grids is their durability. The zinc coating acts as a protective barrier against moisture, chemicals, and environmental stressors, significantly extending the lifespan of the steel. Unlike untreated steel, which can succumb to rust and deterioration over time, galvanised steel remains robust and functional, making it a cost-effective option in the long run. Moreover, the longevity of galvanised steel reduces the need for frequent replacements, which not only saves money but also minimizes environmental impact.

Ekrany węglanowe, znane także jako shale screens, odgrywają coraz większą rolę w procesach wiercenia i produkcji w przemyśle naftowym i gazowym

. W obliczu rosnących wymagań dotyczących efektywności oraz ochrony środowiska, technologia ta staje się kluczowym elementem strategii zarządzania zasobami.