ironing board covers for sale_reflective ironing board cover

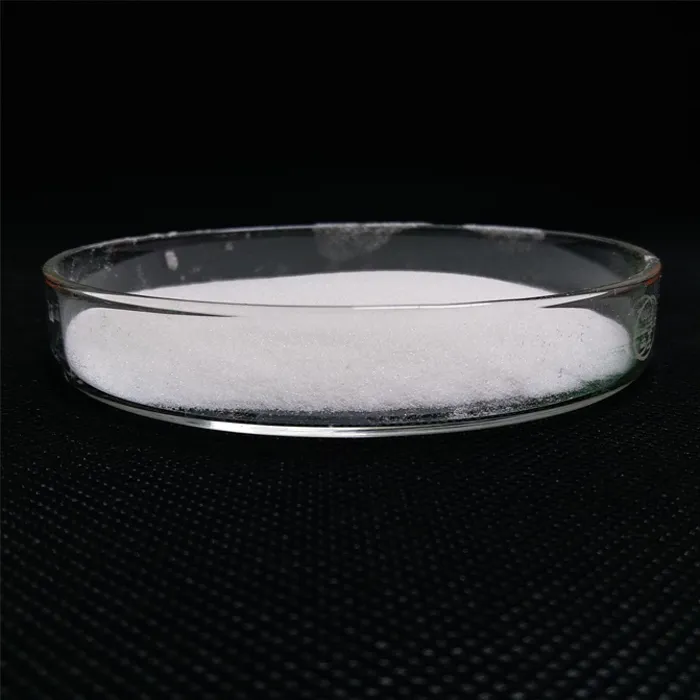

The production of dry polyacrylamide typically involves the polymerization of acrylamide monomers. This can be achieved through various methods, including free radical polymerization, which requires initiators and can occur in aqueous or non-aqueous environments. Once polymerized, the product is often dried, which results in the formation of dry polyacrylamide granules. The drying process is essential to ensure that the polymer retains its effectiveness when reconstituted with water for use in various applications.

dry polyacrylamide

2. Corrosion Inhibitors To protect metal components from oxidation and deterioration, corrosion inhibitors are added to the cooling water. These chemicals form a protective layer on the metal surfaces, preventing corrosive agents present in the water from causing damage. Common inhibitors include phosphates, molybdates, and azoles.

cooling tower water chemicals