In the world of home and event decor, where elegance meets practicality, thick plastic table covers...

2025-08-15 08:15

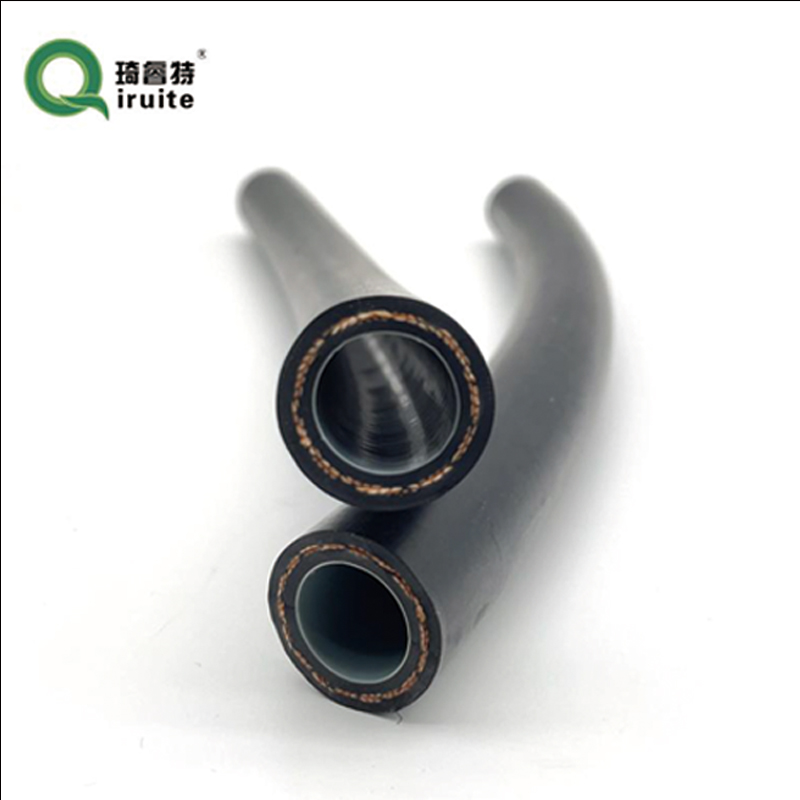

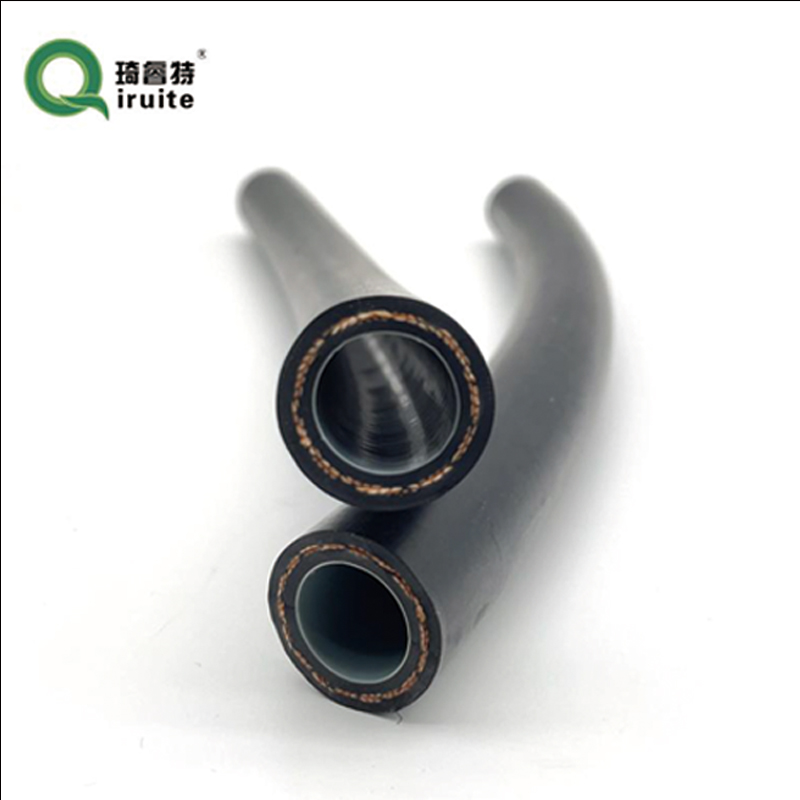

chevelle ls swap power steering hose. A failing hose can lead to erratic steering, compromising vehicle control and driver safety. Therefore, replacing the original equipment with a hose that can cope with the increased demands after an LS swap is not just a performance enhancement but also a critical safety measure. It guarantees precise steering feedback, which is vital for handling the additional power delivered by the LS engine.

chevelle ls swap power steering hose. A failing hose can lead to erratic steering, compromising vehicle control and driver safety. Therefore, replacing the original equipment with a hose that can cope with the increased demands after an LS swap is not just a performance enhancement but also a critical safety measure. It guarantees precise steering feedback, which is vital for handling the additional power delivered by the LS engine. Firstly, they are quicker to install, reducing labor costs and downtime Firstly, they are quicker to install, reducing labor costs and downtime

Firstly, they are quicker to install, reducing labor costs and downtime Firstly, they are quicker to install, reducing labor costs and downtime non threaded pipe coupling. Secondly, they minimize the risk of damage to pipes during the assembly process, as no threading is required. They are also versatile, accommodating different materials like copper, plastic, and stainless steel pipes. Furthermore, they can be easily disconnected for maintenance or repair, making them ideal for applications where frequent changes or adjustments are necessary.

non threaded pipe coupling. Secondly, they minimize the risk of damage to pipes during the assembly process, as no threading is required. They are also versatile, accommodating different materials like copper, plastic, and stainless steel pipes. Furthermore, they can be easily disconnected for maintenance or repair, making them ideal for applications where frequent changes or adjustments are necessary. Signs of a problem may include leaks, cracks, or soft spots in the hose, as well as a decrease in braking performance Signs of a problem may include leaks, cracks, or soft spots in the hose, as well as a decrease in braking performance

Signs of a problem may include leaks, cracks, or soft spots in the hose, as well as a decrease in braking performance Signs of a problem may include leaks, cracks, or soft spots in the hose, as well as a decrease in braking performance power brake booster hose.

power brake booster hose.