cotton ironing board cover_7kg front load washing machine cover

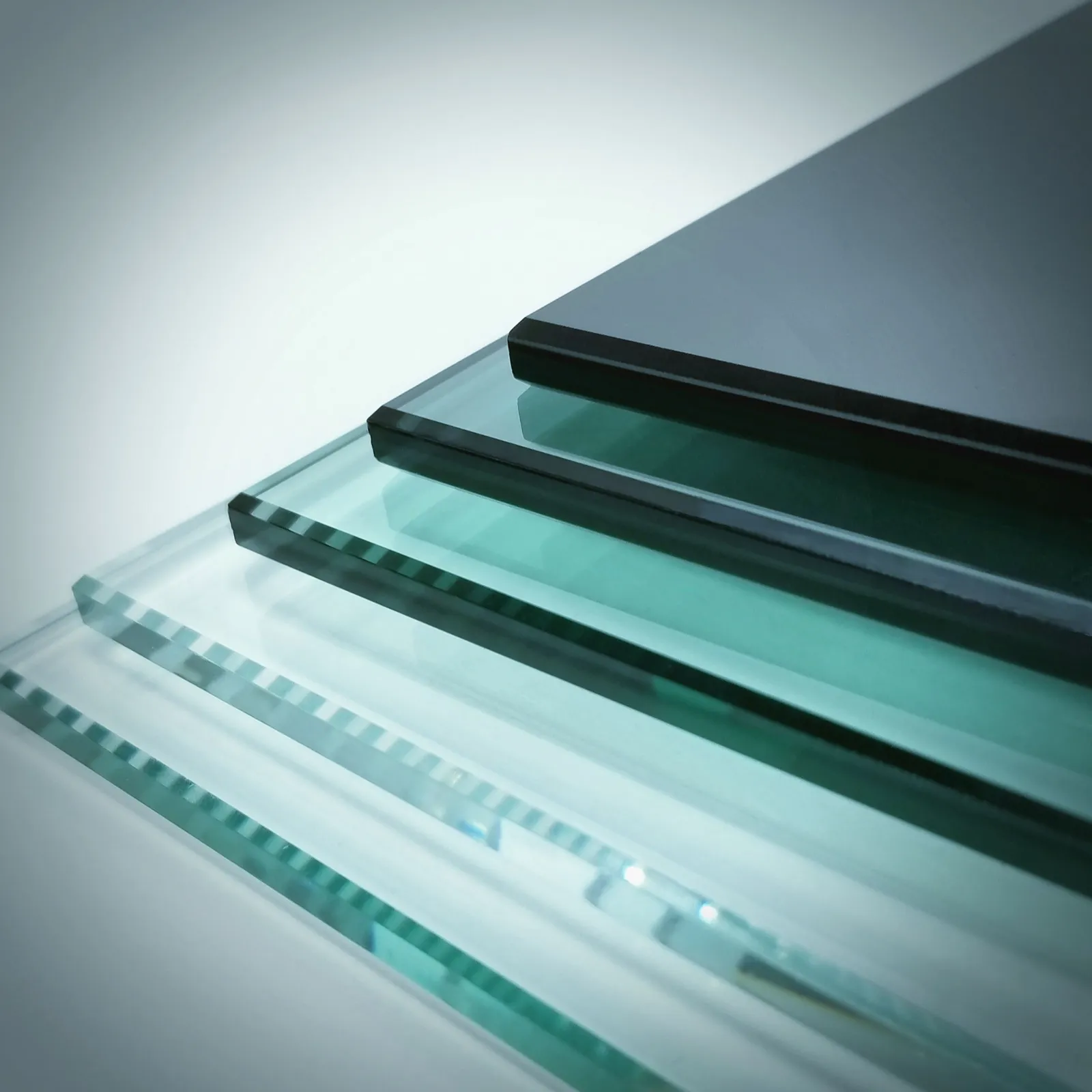

The float glass production process begins with the melting of raw materials, including silica sand, soda ash, and limestone, at high temperatures. This molten mixture is then floated on top of molten tin, allowing the glass to spread evenly and form a continuous sheet. As the glass moves through the annealing lehr—a controlled cooling chamber—it gradually solidifies and is cut into standardized sheet sizes.

float glass sheets

Moreover, the materials used in these mirrors elevate their status. Silver has long been associated with purity and beauty, and its reflective quality enhances the experience of using a mirror. Over time, antique silver develops a patina that adds character and depth, highlighting the uniqueness of each piece. Many collectors appreciate this natural wear as it signifies authenticity and age, enhancing the object's historical narrative.

antique silver mirror handheld

Another benefit of toughened mirror glass is its versatility. It can be used in a variety of applications, from wall mirrors to furniture to decorative accents. Its ability to withstand wear and tear makes it suitable for high-traffic areas, such as entryways or living rooms. Additionally, the reflective quality of the glass can help to enhance the natural light in a room, making it feel brighter and more open.