Key Aspects of Ironing Board Covers

The ironing board cover serves as a critical interface between the ironing tool and fabric, influencing both operational efficiency and textile preservation. Among its variants, the padded ironing board cover has emerged as a focal point in ergonomic research, demonstrating how design elements impact heat transfer and user safety. This scholarly examination explores the technical specifications and usability considerations of these essential accessories, situating them within the broader context of household textile maintenance.

Material Composition of Ironing Board Covers

The structural integrity of ironing board covers hinges on their material composition, with heat-resistant fabrics like cotton-polyester blends dominating industrial standards. These materials exhibit high thermal conductivity and dimensional stability, capable of withstanding high temperatures without degradation—an essential criterion for steam iron compatibility. Tightly woven fabrics minimize fiber penetration, reducing the risk of fabric snags and scorch marks.

For padded ironing board covers, the overlay of foam or felt padding introduces a thermal insulation layer. This padding creates a more uniform temperature distribution across the board surface and acts as a moisture reservoir, preventing condensate accumulation and maintaining consistent ironing pressure.

Ironing board covers with reinforced stitching along stress points further enhance durability, ensuring the cover remains intact under repeated mechanical stress from ironing motions.

Ergonomic Design of Padded Ironing Board Covers

Ergonomic research identifies cushioning density as a pivotal factor in reducing user fatigue during ironing tasks. A padded ironing board cover with optimal resistance to vertical compression minimizes the force required to glide the iron while preventing excessive sinkage that could distort fabric tension. This balance is critical for delicate textiles, where uneven pressure can cause fiber elongation or surface abrasion.Covers with elasticized edges maintain secure positioning during lateral movements, reducing the need for frequent readjustment. Non-slip backing materials enhance operational stability by increasing frictional resistance against the board surface, ensuring consistent performance during use.

The thickness of padded ironing board covers also plays a role in ergonomic design, as it influences the tactile feedback users receive while ironing, impacting both control and comfort.

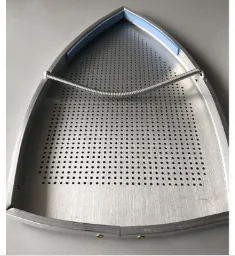

Spatial Adaptations of Tabletop Ironing Board Covers

Tabletop ironing board covers represent a specialized design category addressing spatial constraints in modern living environments. Their compact dimensions necessitate precise engineering to maintain performance parity with full-sized counterparts. Mathematical modeling of heat diffusion in smaller surfaces shows that thoughtful design balances portability with functional efficiency.Material selection for these covers prioritizes lightweight durability, with polycotton blends emerging as the preferred choice due to their high tensile strength and low moisture absorption. Integrated fastening systems ensure a secure fit on boards with varying thicknesses, demonstrating adaptability to diverse product specifications.

Many tabletop ironing board covers feature foldable or collapsible designs, enhancing their utility in small living spaces without compromising on heat resistance or fabric protection.

Aesthetic Considerations of Floral Ironing Board Covers

The incorporation of decorative elements in floral ironing board covers introduces unique technical challenges. Pigment dispersion studies show that certain dyeing methods exhibit superior colorfastness, maintaining vibrancy after repeated industrial wash cycles. Pattern density considerations reduce ink accumulation at stitch points, minimizing fraying risks and balancing aesthetic appeal with functional longevity.Durability testing indicates that embossed floral textures, combined with reinforced seam stitching, enhance mechanical resistance to repeated flexing. These design choices ensure decorative covers meet the same thermal and structural standards as utilitarian models.Floral ironing board covers often utilize eco-friendly inks that comply with international safety standards, ensuring both visual appeal and environmental responsibility in household use.

Padded Ironing Board Covers FAQs

How does padding affect the performance of padded ironing board covers?

Padding in padded ironing board covers creates a thermal insulation layer, improving heat distribution and moisture absorption to enhance wrinkle removal and protect delicate fabrics.

What are key material factors for ironing board covers?

Key material factors for ironing board covers include heat resistance, moisture permeability, and tensile strength, all of which contribute to operational safety and fabric protection.

How are tabletop ironing board covers designed for small spaces?

Tabletop ironing board covers use compact geometries and adaptive fasteners to ensure stability and performance on reduced surfaces, balancing portability with functionality.

What design elements matter for floral ironing board covers?

Design elements like colorfast dyes, pattern density, and reinforced stitching ensure floral ironing board covers maintain both aesthetic appeal and durability through frequent use.

Why is cushioning important in padded ironing board covers?

Cushioning in padded ironing board covers reduces user fatigue by minimizing gliding force while preventing fabric distortion, critical for efficient and safe ironing.

The design and functionality of ironing board covers—particularly padded ironing board covers embody a convergence of material science and ergonomic principles. While technical specifications underpin their performance, adaptive features in compact and decorative variants reflect the industry’s response to evolving consumer needs. Future research might explore innovative materials or smart technologies to further elevate the utility of these essential household tools.

This academic analysis examines ironing board covers, focusing on material composition, ergonomic design, and adaptive solutions for different use cases. Padded ironing board covers highlight the importance of cushioning for efficiency and fabric protection, while tabletop and floral variants demonstrate design trade-offs between functionality and form. Understanding these factors aids in selecting covers that balance performance, durability, and user needs.

-

Shopping Cart Liners A Professional GuideNewsJul.31,2025

-

Professional Heat Glove for Hair Styling EssentialsNewsJul.31,2025

-

Innovations in Iron Shoes for Enhanced Fabric CareNewsJul.31,2025

-

Elevating Laundry Rooms with Washing Machine Hider SolutionsNewsJul.31,2025

-

Choosing the Right Cover for Dining TableNewsJul.31,2025

-

The Future of Footwear: Self-Cleaning Teflon Iron ShoesNewsJul.04,2025

-

Stylish Shopping Trolley Liners: Fashion Meets FunctionNewsJul.04,2025