The textile industry continuously evolves with innovations that enhance safety and productivity. At the forefront of this evolution is the Iron Glove, a groundbreaking safety accessory developed by industry experts. This essential tool protects professionals from burns and improves the efficiency of textile pressing operations worldwide.

About Our Company

Hebei Machinery & Equipment Import & Export Co., Ltd. is a global leader in textile machinery and safety equipment. With decades of expertise, we supply premium solutions to professionals worldwide, prioritizing safety, innovation, and reliability.

Introducing the Revolutionary Iron Glove

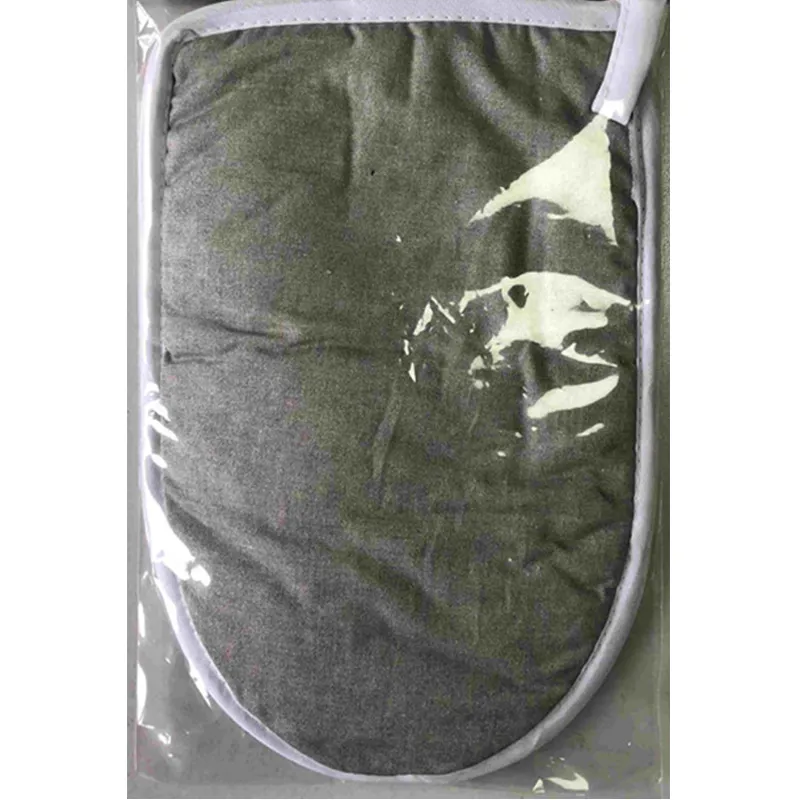

The Iron Glove is an indispensable safety accessory for textile professionals working with steam irons and pressing equipment. Designed with innovative materials, this protective gear eliminates the risk of hand burns while handling high-temperature pressing tools.

Constructed with silicone-coated 100% cotton fabric exterior and reinforced with a thick sponge interlayer, the Iron Glove provides unparalleled protection, comfort, and practicality in demanding textile environments.

View Product Details

Industry Applications and Use Cases

The Iron Glove serves multiple industries beyond textiles, including:

Professional Tailoring

All-day protection for tailors using industrial pressing equipment with constant steam exposure

Hospitality Laundry

Essential for hotel staff handling high-volume pressing machinery safely

Dry Cleaning Facilities

Protection during specialized garment treatment with steam presses

Technical Specifications

The Iron Glove incorporates advanced materials engineering for maximum protection:

| Parameter | Specification | Industry Standard |

|---|---|---|

| Material Composition | Silicone coated 100% cotton exterior, thick sponge interlayer | Exceeds EN388:2016 |

| Heat Resistance | Up to 300°C continuous exposure | 250°C |

| Thermal Insulation | Maintains 35°C hand temperature at 200°C surface contact | Typically maintains 45-50°C |

| Grip Enhancement | Silicone patterned surface for secure handling (0.8 coefficient) | 0.4-0.6 coefficient |

| Durability | 500+ industrial pressing cycles before replacement | 200-300 cycles |

| Ergonomic Design | Pre-curved finger positions with natural flex zones | Flat-palm design |

Performance Metrics and Industry Trends

The effectiveness of the Iron Glove is validated through extensive laboratory testing and industry adoption statistics. As textile safety standards evolve (ISO 12127-1:2015), innovation in thermal protection becomes increasingly crucial.

Thermal Performance Comparison

Market Adoption Trends (2018-2023)

Professional FAQ: Technical Aspects of Iron Glove

Industry References and Technical Citations

"Advancements in Thermal Protective Materials for Textile Processing" - Journal of Industrial Textiles, 2021. https://www.journalofindustrialtextiles.com/article/thermal-protection

ISO Standards Committee Report: "Heat Transfer through Protective Materials" (ISO/TR 22681:2020). https://www.iso.org/standard/22681

Textile Safety Research Group: "Comparative Evaluation of Steam Handling PPE" - 2022 Industry White Paper. https://www.textilesafety.org/steam-ppe-study

Global Textile Equipment Association: "Ergonomic Improvements in Pressing Safety" (2023 Conference Proceedings). https://www.gteaconference.org/proceedings/ergonomics

European Review of Industrial Safety Equipment: "Material Innovation in Thermal Protection" - Volume 15, Issue 3. https://erise-journal.eu/vol15-issue3