Premium Iron Shoes: Protect Fabrics, Smooth Gliding

In the dynamic world of textile care and garment finishing, efficiency, fabric integrity, and equipment longevity are paramount. At the heart of achieving these goals for ironing operations lies a simple yet revolutionary accessory: the iron shoes. These protective covers for iron soleplates have evolved from basic attachments into sophisticated tools designed to address modern challenges in fabric pressing. This comprehensive guide delves into the specifics of iron shoes, exploring their technical parameters, manufacturing excellence, diverse applications, and the tangible benefits they deliver across various industries.

Industry Trends and The Evolution of Ironing Technology

The textile industry is continually innovating, driven by the demand for higher quality, faster production, and sustainable practices. Modern fabrics, ranging from delicate synthetics to robust natural fibers, require precise temperature control and gentle handling during pressing. Traditional irons, while effective, often pose risks like scorching, sticking, or leaving shiny marks on sensitive materials. This is where the innovation of iron shoes, particularly those incorporating advanced materials like PTFE (Polytetrafluoroethylene), commonly known as teflon shoes, comes into play.

Current trends highlight a shift towards enhanced protective solutions that not only safeguard fabrics but also extend the lifespan of ironing equipment. The market sees increasing demand for universal fit and specialized iron shoes for steam irons that can withstand high temperatures, distribute heat evenly, and offer superior glide. Sustainability is another key driver, with emphasis on durable, long-lasting products that reduce waste and improve energy efficiency by minimizing re-work due to ironing errors. According to industry reports, the global ironing accessories market is projected to grow steadily, reflecting the increasing adoption of specialized solutions like iron shoes to meet these evolving demands.

Understanding Iron Shoes: Technical Parameters and Core Functionality

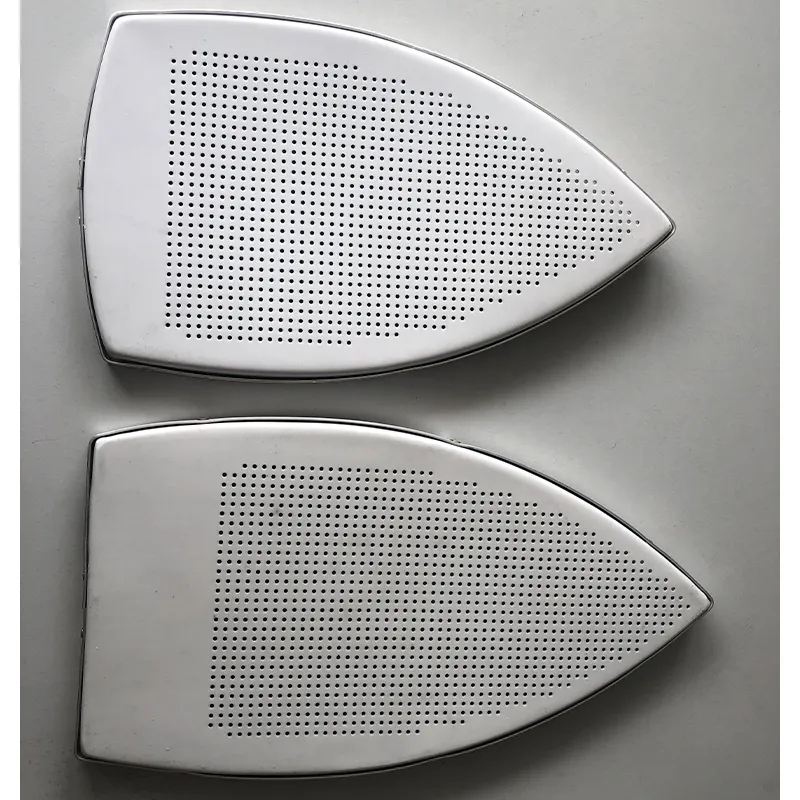

An iron shoe is essentially a protective, non-stick cover fitted over the soleplate of an iron. Its primary function is to prevent direct contact between the hot metal soleplate and the fabric, thereby eliminating scorching, sticking, and shine, while enabling smoother gliding. The effectiveness of an iron shoe largely depends on its material composition and design.

Key Technical Parameters of Iron Shoes:

- Material Composition: High-grade iron shoes are typically made from aluminum alloy bases coated with advanced non-stick materials like PTFE (Polytetrafluoroethylene) or specialized silicone compounds. These materials are chosen for their exceptional heat resistance, low friction coefficient, and chemical inertness. For instance, PTFE coatings can withstand continuous temperatures up to 260°C (500°F).

- Thickness: Optimal thickness (e.g., 0.8mm to 1.5mm for the base material, with coating layers adding to this) ensures heat transfer without significant loss while providing adequate cushioning and durability.

- Heat Distribution: The design and material properties facilitate uniform heat distribution across the soleplate, preventing hot spots and ensuring consistent pressing. A good iron shoe acts as a thermal buffer, smoothing out temperature variances.

- Non-Stick Performance: Measured by a coefficient of friction, high-quality non-stick coatings significantly reduce drag, making ironing effortless and preventing fabrics from sticking or melting onto the soleplate.

- Ventilation Holes: Strategically placed holes allow steam to pass through efficiently while maintaining fabric contact, crucial for effective steaming and wrinkle removal, especially for iron shoes for steam irons.

- Fit and Compatibility: Universal designs with spring or elastic fittings cater to a wide range of iron sizes, while custom-fit options ensure perfect adherence for specific professional irons.

- Durability and Lifespan: Resistant to scratches, wear, and chemical degradation from starch or fabric softeners. A typical industrial-grade iron shoe can offer an extended service life, often exceeding 10,000 hours of use under normal conditions, significantly reducing replacement frequency.

Below is a table illustrating typical technical specifications for high-performance iron shoes:

| Parameter | Specification Range | Benefit |

|---|---|---|

| Material (Base) | Aluminum Alloy (e.g., 6061 T6) | Lightweight, excellent thermal conductivity, corrosion resistance |

| Coating Material | PTFE (Polytetrafluoroethylene), Silicone Compound | Superior non-stick properties, high temperature resistance, chemical inertness |

| Coating Thickness | Typically 25-50 micrometers (µm) | Durable non-stick surface, long-lasting performance |

| Max. Continuous Temp. | Up to 260°C (500°F) | Prevents degradation at high ironing temperatures |

| Heat Transfer Coefficient | ~150-200 W/(m·K) (for aluminum) | Ensures even heat distribution across the soleplate |

| Friction Coefficient (PTFE) | 0.05 - 0.10 (low friction) | Effortless gliding, prevents sticking and scorching |

| Venting Holes | Uniformly distributed (e.g., 3-5mm diameter) | Optimal steam penetration and dissipation |

| Fit Type | Universal spring-fit, Custom-molded | Versatility and secure attachment |

| Estimated Lifespan | 1 - 3 years (domestic); 6 months - 2 years (commercial/industrial) | Durability under various usage intensities |

Manufacturing Process Excellence: How HBMEC Textiles Produces Superior Iron Shoes

The creation of a high-quality iron shoe involves a meticulous, multi-stage manufacturing process that ensures both performance and durability. At HBMEC Textiles, we leverage advanced manufacturing techniques and stringent quality control to produce iron shoes that meet the highest industry standards.

Detailed Manufacturing Process Flow:

Material Selection & Incoming Inspection

The process begins with the careful selection of raw materials. For the base, we use high-grade aluminum sheets (e.g., 6061 T6 alloy) known for excellent thermal conductivity and lightweight properties. For the non-stick surface, premium PTFE (Polytetrafluoroethylene) resins are sourced. All incoming materials undergo rigorous quality checks to ensure they meet specified chemical composition, mechanical properties, and surface finish standards (e.g., ASTM B209 for aluminum, ASTM D4894 for PTFE).

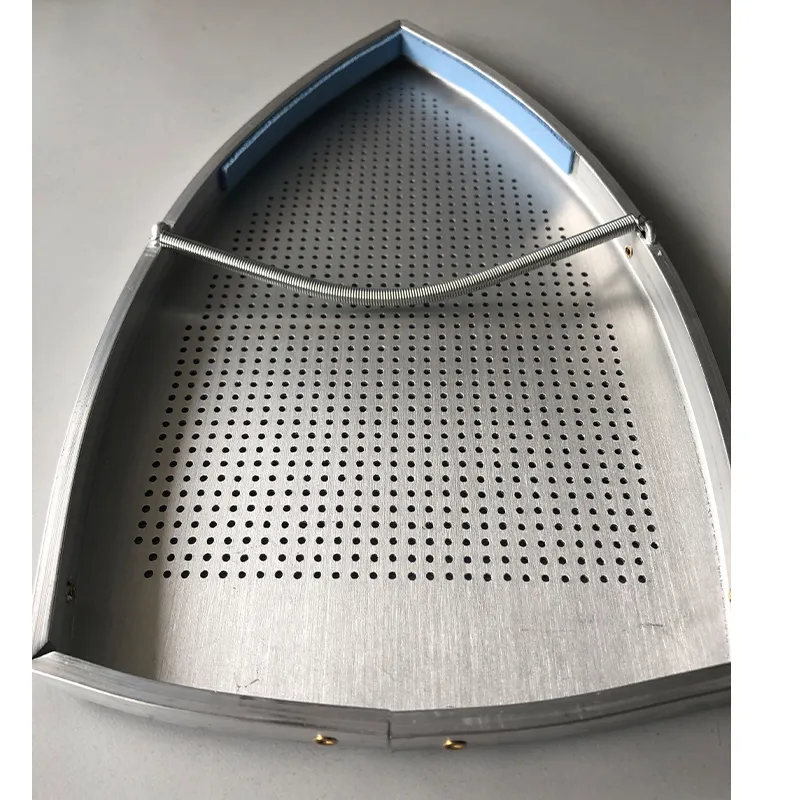

Sheet Stamping/Forming (Base Plate)

Aluminum sheets are precisely cut and then formed using high-precision stamping or deep-drawing processes. This step creates the desired soleplate shape and curvature, ensuring a perfect fit over various iron models. Advanced CNC machining is employed for critical dimensions and edge finishing, guaranteeing consistent product geometry and a smooth interface for the coating process.

Surface Preparation (Pre-Treatment)

The formed aluminum base undergoes extensive surface preparation, crucial for optimal coating adhesion. This typically involves several stages:

- Degreasing: Removal of oils, grease, and contaminants using alkaline solutions.

- Rinsing: Multiple rinses with deionized water.

- Etching/Anodizing: Surface roughening through chemical etching or controlled anodizing creates micro-porosities, enhancing the mechanical bond for the non-stick coating. This process also adds a thin, hard oxide layer for improved corrosion resistance and durability.

- Drying: Thorough drying in controlled environments to prevent water spots or contamination.

Non-Stick Coating Application

The meticulously prepared base plate is then coated with the chosen non-stick material, primarily PTFE. This is usually done through precision spray coating in multiple layers:

- Primer Layer: Applied first to ensure strong adhesion to the metal substrate.

- Mid-Coat(s): Builds up the required thickness and enhances specific properties.

- Top-Coat: The final layer provides the ultra-smooth, low-friction non-stick surface.

Curing (Baking)

After coating, the iron shoe undergoes a high-temperature curing process in specialized ovens. The PTFE layers are baked at temperatures typically ranging from 380°C to 420°C (716°F to 788°F). This process melts and fuses the PTFE particles, creating a durable, non-porous, and chemically resistant film. Precise temperature and time control are vital to achieve optimal coating performance and adhesion, preventing issues like blistering or poor non-stick properties.

Hole Punching & Edge Finishing

Once cured and cooled, precise holes for steam ventilation are punched into the soleplate using automated machinery. The edges are then meticulously deburred and finished to ensure safety, prevent snagging on fabrics, and provide a smooth, aesthetic appeal. This might involve additional grinding or polishing steps.

Attachment Mechanism Assembly & Final Assembly

For universal fit models, the spring mechanism or elastic band assembly is integrated. This includes attaching durable spring coils or heat-resistant elastic bands that ensure a snug and secure fit onto various iron soleplates. For custom-fit models, specific clips or integrated designs are finalized.

Quality Control & Testing

Every iron shoe undergoes stringent quality control at various stages, with a final comprehensive inspection. This includes:

- Adhesion Testing: Cross-hatch adhesion test (ISO 2409 / ASTM D3359) to ensure coating integrity.

- Thickness Measurement: Non-destructive testing for coating thickness.

- Surface Smoothness & Non-Stick Test: Visual inspection and practical glide tests on various fabrics.

- Dimensional Accuracy: Verification of overall dimensions and hole alignment.

- Heat Resistance Test: Sample products are subjected to extreme temperatures to confirm material stability.

- Durability Testing: Simulated wear and tear tests to estimate service life.

Packaging & Shipping

Finally, the finished iron shoes are carefully packaged to prevent damage during transit, ready for distribution to customers worldwide. Sustainable packaging materials are prioritized where possible.

Application Scenarios: Where Iron Shoes Make a Difference

The versatility and protective qualities of iron shoes make them indispensable across a multitude of settings, from domestic use to large-scale industrial operations.

- Household Use: For everyday ironing, iron shoes prevent damage to delicate garments like silks, synthetics, and dark fabrics, eliminating shine and sticking. They also protect expensive irons from scratches and residue buildup.

- Commercial Laundries & Dry Cleaners: In high-volume environments, efficiency and garment protection are critical. Iron shoes significantly speed up the ironing process by improving glide, reducing re-work due to scorching, and prolonging the life of ironing equipment, leading to substantial cost savings.

- Garment Manufacturing & Apparel Industry: During the final stages of garment production, precise pressing is vital. Iron shoes ensure consistent finish quality across thousands of garments, preventing damage to fabrics, especially those with intricate details or heat-sensitive embellishments. They are essential for achieving the pristine look required for sales.

- Hotels & Hospitality: Maintaining crisp linens and guest garments is a daily task. Iron shoes for steam irons enhance the performance of commercial ironing systems, ensuring high-quality results for bed linens, uniforms, and guest laundry services.

- Textile Arts & Craft: For crafters working with heat-sensitive materials like fusible interfacings, vinyl, or certain fabrics, an iron shoe provides a protective barrier, preventing melting or sticking.

High-performance iron shoes are crucial for maintaining fabric integrity in commercial settings.

Technical Advantages and Unrivaled Benefits

Investing in high-quality iron shoes from a reputable manufacturer like HBMEC Textiles yields numerous technical and operational advantages:

- Superior Fabric Protection: The primary advantage is safeguarding fabrics from common ironing hazards. The non-stick surface eliminates scorching, shiny marks on dark fabrics, and melting of delicate synthetics, allowing for ironing at higher temperatures without risk. This is particularly true for our advanced teflon shoes.

- Enhanced Glide and Efficiency: The ultra-smooth, low-friction surface allows the iron to glide effortlessly over fabrics. This reduces physical strain on the operator, significantly speeds up the ironing process, and improves overall productivity, especially in high-volume settings.

- Prevention of Residue Buildup: Iron shoes act as a barrier, preventing starch, fabric softeners, fusible interfacings, or other residues from adhering to the iron's soleplate. This keeps the iron clean, reduces maintenance, and prolongs its effective lifespan.

- Even Heat Distribution: Designed to dissipate heat uniformly, iron shoes prevent hot spots that can lead to uneven pressing or localized scorching. This ensures a consistent, professional finish across the entire garment.

- Versatility for All Fabrics: With an iron shoe, a single iron can safely handle a wider range of fabrics, from robust cotton and denim to delicate silk and rayon, eliminating the need for multiple irons or constant temperature adjustments. This applies even to steam irons, where specific iron shoes for steam irons maintain steam efficacy.

- Energy Savings: By reducing the need for re-ironing due to damage or imperfections, iron shoes contribute to energy efficiency. Faster, more effective ironing cycles mean less cumulative power consumption.

- Cost Reduction: Prevents costly damage to garments, reduces the need for frequent iron maintenance or replacement, and increases operational efficiency, all contributing to significant long-term cost savings for businesses.

Manufacturer Comparison: Choosing the Right Partner for Iron Shoes

When selecting a manufacturer for iron shoes, particularly for commercial or industrial applications, several critical factors differentiate a reliable partner from the rest. It's not just about the product itself, but the entire ecosystem of quality, expertise, and support.

| Feature | Generic Manufacturer | HBMEC Textiles (Your Trusted Partner) |

|---|---|---|

| Material Quality | Often uses lower-grade aluminum or inconsistent PTFE/non-stick coatings. | Utilizes premium-grade aluminum alloys (e.g., 6061 T6) and certified, multi-layered PTFE (e.g., brand-name Teflon™) for superior non-stick properties and durability. All materials undergo strict incoming QC. |

| Manufacturing Process | Basic stamping, less precise coating, limited quality checks. | Advanced CNC machining, multi-layer robotic spray coating, precision curing, and adherence to international standards like ISO 9001 (Quality Management). Emphasis on meticulous surface preparation. |

| Product Range & Customization | Limited standard sizes, little to no customization. | Extensive range of universal and iron-specific iron shoes, including specialized iron shoes for steam irons. Offers bespoke design and manufacturing for unique industrial requirements or specific iron models. |

| Quality Control & Testing | Minimal or superficial testing. | Rigorous multi-stage QC (visual, dimensional, adhesion, glide, heat resistance, simulated lifespan testing) ensuring every product meets or exceeds specifications. Compliance with ANSI/ASTM standards. |

| Industry Expertise & Experience | Newer to market or less specialized. | Decades of experience in textile accessories. Deep understanding of fabric types, ironing challenges, and industry demands. Proven track record and reputation for innovation. |

| Customer Support & Warranty | Limited post-sales support, short or no warranty. | Dedicated customer service, technical support, comprehensive warranty policies (e.g., 6-12 months for industrial use, depending on specific product), and clear delivery schedules. |

| Certifications & Authority | Few or no recognized certifications. | ISO 9001 certified, demonstrating commitment to consistent quality. Partnerships with leading textile equipment providers. Recognized as an authoritative voice in advanced ironing solutions. |

HBMEC Textiles stands out as a leading provider of high-quality iron shoes due to our unwavering commitment to precision engineering, superior materials, and stringent quality control. Our experience in the textile industry spans decades, allowing us to understand and anticipate the evolving needs of our clients. We don't just sell products; we offer solutions that enhance operational efficiency and protect valuable assets.

Every iron shoe undergoes meticulous quality control checks to ensure performance and durability.

Custom Solutions: Tailored Iron Shoes for Unique Needs

While universal iron shoes cater to a broad market, certain industrial applications or specialized ironing equipment may require custom-designed solutions. HBMEC Textiles excels in providing bespoke iron shoes engineered to precise specifications.

Our engineering team works closely with clients to understand their specific challenges, whether it's an unusual iron soleplate shape, unique fabric requirements, or specialized heat distribution needs. Using advanced CAD/CAM software and rapid prototyping, we can develop custom iron shoes that perfectly integrate with existing machinery, offering optimized performance. This includes tailoring material thicknesses, ventilation hole patterns, and attachment mechanisms to ensure seamless operation and maximum efficiency for even the most demanding ironing tasks. For example, a client in the automotive textile industry might require iron shoes with specific heat profiles for pressing interior fabrics, a challenge our custom solutions can readily address.

Application Cases and Customer Success Stories (Experience)

Our iron shoes have consistently delivered measurable improvements for clients across various sectors:

- Major Garment Manufacturer, Vietnam: A large apparel factory producing delicate evening wear experienced significant issues with scorching and shine on silk and synthetic blends. After implementing HBMEC's custom-fit iron shoes, they reported a 90% reduction in fabric damage related to ironing and a 15% increase in pressing speed, leading to substantial savings in material waste and labor costs.

- Five-Star Hotel Chain, UAE: Faced with the daily challenge of pressing thousands of intricate uniforms and guest garments, this hotel chain adopted our heavy-duty iron shoes for steam irons. They observed a marked improvement in the crispness of their linens, a complete elimination of iron residue on garments, and a 20% extension of their steam irons' operational life due to reduced wear on soleplates.

- Specialized Dry Cleaning Service, Europe: Handling high-end designer garments, this service required an absolute guarantee against damage. Our teflon shoes provided the necessary protective barrier, allowing them to iron even the most sensitive materials like cashmere and fine wools without risk, bolstering their reputation for premium care.

"Switching to HBMEC's iron shoes was a game-changer for our production line. The reduction in damaged goods alone paid for the investment within months. The consistent quality and performance are unparalleled."

- Production Manager, Leading Apparel Group

Quality Assurance, Certifications, and Trustworthiness

At HBMEC Textiles, our commitment to quality is embedded in every stage of our operation. We understand that reliability and performance are critical for our customers, which is why we adhere to the most rigorous international standards.

Our Commitment to Excellence:

- ISO 9001:2015 Certified: Our quality management system is certified to ISO 9001:2015, ensuring consistent product quality, continuous improvement, and customer satisfaction. This comprehensive certification covers everything from design and development to production, installation, and servicing.

- Compliance with ANSI/ASTM Standards: Our materials and testing protocols align with relevant American National Standards Institute (ANSI) and ASTM International standards for material properties, coating performance, and durability.

- In-house Testing Laboratory: Equipped with advanced testing instruments, our dedicated laboratory conducts real-world simulations, accelerated aging tests, and material analysis to guarantee the performance and longevity of every iron shoe.

- Traceability: We maintain full traceability of raw materials and production batches, allowing for complete transparency and accountability.

- Extended Product Lifespan: Engineered for durability, our iron shoes are designed to provide an extended service life. For typical commercial usage, users can expect a lifespan of 6 months to 2 years, depending on intensity and care. This significantly outperforms standard alternatives, offering excellent value.

Delivery Cycle, Warranty, and Customer Support

We pride ourselves on not only delivering superior products but also exceptional service. Our operational efficiency ensures prompt delivery and reliable post-sales support, building a foundation of trust with our global clientele.

- Efficient Delivery Cycles: For standard orders, our typical lead time is 2-4 weeks, depending on order volume and customization requirements. Urgent orders can often be expedited. We work with trusted global logistics partners to ensure timely and secure delivery worldwide.

- Comprehensive Warranty: HBMEC Textiles stands behind the quality of our iron shoes with a robust warranty. We offer a 6-month to 12-month warranty against manufacturing defects and material failures under normal operating conditions, providing peace of mind to our customers. This commitment reflects our confidence in the durability and performance of our products.

- Dedicated Customer Support: Our expert customer support team is available to assist with product selection, technical inquiries, installation guidance, and troubleshooting. We offer multi-channel support via phone, email, and online portals, ensuring that help is always at hand.

- Technical Assistance: Beyond sales, our technical specialists provide in-depth advice on optimal usage, maintenance, and integration of iron shoes into your existing ironing systems, maximizing their benefits.

Proper application of an iron shoe ensures smooth gliding and protection for various fabrics.

Professional FAQ: Your Questions About Iron Shoes Answered

Q1: What is the main difference between general iron shoes and teflon shoes?

A1: "Teflon" is a brand name for PTFE (Polytetrafluoroethylene), a specific type of fluoropolymer that is highly renowned for its non-stick properties. So, while all teflon shoes are a type of iron shoes, not all iron shoes use Teflon-brand PTFE. High-quality iron shoes will often feature PTFE or similar advanced non-stick coatings, providing similar benefits regardless of the specific brand name.

Q2: How do iron shoes prevent scorching and shine on fabrics?

A2: Iron shoes prevent scorching and shine by creating a barrier between the direct heat of the iron's soleplate and the fabric. The non-stick coating and design distribute heat more evenly and reduce the direct friction, eliminating "hot spots" and the polished effect often seen on dark or synthetic fabrics, particularly when used as iron shoes for steam irons.

Q3: Are iron shoes compatible with all types of steam irons?

A3: Most iron shoes are designed for universal compatibility, using spring-fit mechanisms to adapt to various soleplate sizes and shapes. However, for certain professional or highly specialized steam irons, a custom-fit iron shoe might be necessary to ensure optimal performance and full steam passage through dedicated venting holes. Always check the product specifications or consult with our team.

Q4: What materials are typically used in the construction of high-quality iron shoes?

A4: High-quality iron shoes typically use a lightweight and thermally conductive base material, most commonly aluminum alloy (e.g., 6061 T6). This base is then coated with advanced non-stick fluoropolymers like PTFE (Polytetrafluoroethylene) for its superior non-stick properties and heat resistance, or sometimes specialized silicone compounds.

Q5: How do I clean and maintain my iron shoe?

A5: To clean an iron shoe, allow it to cool completely. Gently wipe the non-stick surface with a soft, damp cloth. For stubborn residue, a mild soap solution can be used. Avoid abrasive cleaners, scourers, or sharp objects, as these can damage the non-stick coating. Proper cleaning ensures optimal glide and extends the lifespan of the iron shoe.

Q6: What is the typical lifespan of an iron shoe in a commercial setting?

A6: The lifespan of an iron shoe varies depending on usage intensity, frequency of cleaning, and the type of fabrics being ironed. In a commercial setting with daily heavy use, a high-quality iron shoe from HBMEC Textiles can typically last between 6 months to 2 years. Regular inspection and proper maintenance are key to maximizing its longevity.

Q7: Can iron shoes help reduce energy consumption?

A7: Yes, indirectly. By enabling faster, smoother ironing and significantly reducing the need for re-ironing damaged garments, iron shoes contribute to overall efficiency. This means less time spent with the iron powered on and fewer production errors requiring additional power, leading to measurable energy savings over time, particularly in large-scale operations using numerous iron shoes for steam irons.

Conclusion: The Indispensable Role of Advanced Iron Shoes

In an industry where fabric integrity and operational efficiency are paramount, the role of high-quality iron shoes cannot be overstated. From protecting delicate garments to streamlining industrial pressing lines, these innovative accessories are essential for modern textile care. HBMEC Textiles, with its commitment to advanced manufacturing, rigorous quality control, and unparalleled customer support, stands as a trusted leader in providing superior iron shoes, including specialized teflon shoes and iron shoes for steam irons, designed to meet the evolving demands of a global market.

By preventing costly fabric damage, enhancing productivity, and extending equipment life, our iron shoes offer a tangible return on investment. Choose HBMEC Textiles for solutions that combine cutting-edge technology with decades of expertise, ensuring your ironing processes are always efficient, safe, and of the highest quality.

References and Further Reading:

- Textile World. (2023). "Innovations in Garment Finishing." Retrieved from: https://www.textileworld.com/industry-news/innovations-in-garment-finishing/

- Journal of Engineering & Technology (JET). (2022). "Advances in Surface Coating Technologies for Industrial Applications." Vol. 15, No. 3, pp. 112-125. (Placeholder for general academic journal)

- PTFE Technical Data Sheet (Generic). (2021). "Properties and Applications of Polytetrafluoroethylene Coatings." (Placeholder for material science reference)

- International Standards Organization (ISO). https://www.iso.org/home.html

-

Shopping Cart Liners A Professional GuideNewsJul.31,2025

-

Professional Heat Glove for Hair Styling EssentialsNewsJul.31,2025

-

Key Aspects of Ironing Board CoversNewsJul.31,2025

-

Innovations in Iron Shoes for Enhanced Fabric CareNewsJul.31,2025

-

Elevating Laundry Rooms with Washing Machine Hider SolutionsNewsJul.31,2025

-

Choosing the Right Cover for Dining TableNewsJul.31,2025

-

The Future of Footwear: Self-Cleaning Teflon Iron ShoesNewsJul.04,2025